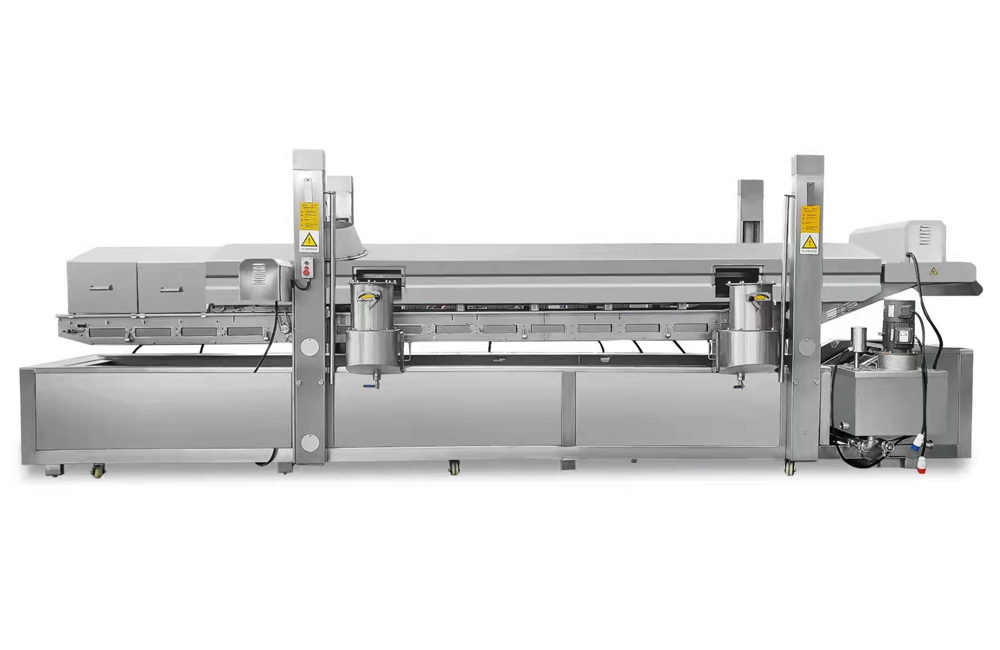

Continuous frying machine

The frying machine adopts oil-water mixed slag filtering structure and full oil longitudinal slag scraping or side scraping system, with variable frequency speed regulation. When frying, the residue of the fried product sinks into the water under the oil tank, the residue will not form carbon, and can be discharged through the drain valve together with the water. At the same time, a large amount of edible oil contained in the residue returns to the oil layer after oil-water separation. In this way, the service life of the oil is greatly prolonged, the oil consumption is reduced, the oil saving effect is very obvious, and the fried product has better color, aroma and taste, and the appearance is cleaner and beautiful. The machine is equipped with a lifting system, which can lift the conveyor to an appropriate height, making the cleaning and maintenance of the machine very convenient. It is suitable for users whose frying time is within 15 seconds to 8 minutes. After technical treatment, the machine can adapt to different energy sources to meet the different requirements of users. This machine is especially suitable for large, medium and small enterprises.

Main Features:

1. Continuous belt frying machine is designed for automatic working

2. Suitable for different foods

3. High capacity and high quality

4. Made of SUS304

5. Frying time and temperature can be adjusted based on request suitable for different foods.

6. Various frying production lines can be customized according to requirements

7. Mesh belt transmission adopts frequency infinitely adjustable-speed, frying time can be controlled.

8. Equipment with automatic lifting system, easy to clean

9. Suit for processing the vegetables, the cooked wheaten food, the aquatic products, snacks etc.

10. Automatic PLC control and easy for use

11. Equipped with automatic fire extinguishing system

Main Features:

1. Continuous belt frying machine is designed for automatic working

2. Suitable for different foods

3. High capacity and high quality

4. Made of SUS304

5. Frying time and temperature can be adjusted based on request suitable for different foods.

6. Various frying production lines can be customized according to requirements

7. Mesh belt transmission adopts frequency infinitely adjustable-speed, frying time can be controlled.

8. Equipment with automatic lifting system, easy to clean

9. Suit for processing the vegetables, the cooked wheaten food, the aquatic products, snacks etc.

10. Automatic PLC control and easy for use

11. Equipped with automatic fire extinguishing system

|

New Type Frying Machine Technical Specifications |

|||||||

|

Model |

Dimension (mm) |

Belt Width(mm) |

Heating Area(㎡) |

Freezing Capacity (Kg/h) |

Heating Time(15S-150S) | Machine Power(KW) | Heat Transfer Oil Flow(L/min) |

| JME6050 | 5050*2500*2500 | 600 | 2.4 | 750 | 18 | 130-160 | 0 |

| JME7080 | 8050*2600*2500 | 700 | 4.9 | 1500 | 18 | 280-350 | 0 |

| JME8080 | 8050*2700*2500 | 800 | 5.6 | 2000 | 18 | 320-410 | 0 |

| JME10090 | 9050*2800*2500 | 1000 | 8.0 | 3000 | 18 | 460-565 | 0 |

| JMO6050 | 5050*2500*2500 | 600 | 2.4 | 1200 | 18 | 190-210 | 300 |

| JMO7080 | 8050*2600*2500 | 700 | 4.9 | 2000 | 18 | 410-460 | 650 |

| JMO8080 | 8050*2700*2500 | 800 | 5.6 | 2500 | 18 | 460-530 | 750 |

| JMO10090 | 9050*2800*2500 | 1000 | 8.0 | 3500 | 18 | 670-750 | 1050 |

|

Referenced product |

Fried chicken popcorn |

Shallow frying after forming and coating | |||||

|

Optional |

Mesh belt width,pot body length,heating method(eletric heating or heat transfer oil) | ||||||

PRODUCT APPLICATION:

Feedback form contact with us